Quick-connectors are connectors or fittings to match fluid lines with machinery that necessitates frequent connections and disconnections. They connect with a simple push and are made simple to operate without tools. Quick connectors are utilized in hydraulic or pneumatic systems, particularly in time-sensitive situations requiring a quick technique to join lines without losing fluid pressure. Quick connections are made to be simple to operate by hand and are typically used with fitting attachments on mobile machinery. Several other names in the water treatment business, including connectors and adapters, refer to fittings. Read More…

Kent Rubber Supply has been a trusted supplier of industrial couplings and fittings since 1946. Offering all of the connections that you need for your industrial fitting, securement, accessories, and industrial coupling needs. Using our up-to-date assembly process, we can confidently supply all your coupling and fitting solutions.

At Ryan Herco Flow Solutions, we are dedicated to providing high-quality quick release couplings that keep our customers’ fluid handling systems operating with efficiency and reliability. Our quick release couplings are engineered to deliver secure, leak-free connections while allowing fast and easy disconnection, reducing downtime and simplifying maintenance across a wide range of applications.

At VACCO Industries, we take pride in being a trusted provider of precision-engineered solutions that serve demanding applications across aerospace, defense, and industrial markets. Our expertise extends to the design and manufacturing of quick disconnect couplings that are built to deliver reliable performance in critical environments.

At Dixon Valve and Coupling Company, we take pride in being a trusted leader in the design and manufacture of high-quality quick disconnect couplings that keep industries moving efficiently and safely. Our quick disconnects are engineered for reliability, allowing operators to easily connect and disconnect hoses, lines, and equipment without tools or leakage.

CEJN® manufactures several types of couplings, including quick connect couplings, hose couplings and hydraulic couplings that are applied in the areas of pneumatics, breathing air, hydraulics and other fluids. For over 40 years, we have been a mainstay for applications in pneumatics, water and chemicals.

Since 1969, Safeway, a division of The Specialty Mfg. Co. has been a manufacturer of quick action couplings, hydraulic couplings, and other quick couplings in a variety of materials and sizes, with numerous thread styles available. Our quick couplings are standard on skid-steer loaders, agricultural, construction, mining, rescue, mobile and off-shore equipment. All of our products are made 100%...

More Quick Connector Manufacturers

Comprehensive Guide to Quick Connectors: Types, Applications, and Selection Tips

Quick connectors—also known as quick connect fittings, quick release couplings, or quick disconnects—are essential components in a vast array of industrial, commercial, and even residential applications. These specialized fittings enable rapid and reliable connection and disconnection of fluid lines, pneumatic hoses, and other tubing systems without the need for special tools. If you’re looking for quick connectors for fluid transfer, air systems, hydraulic circuits, or laboratory setups, understanding their working principles, types, benefits, and how to choose the right manufacturer is crucial for making an informed purchasing decision.

Working Principle of Quick Connectors

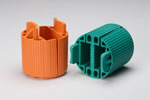

The quick connector's straightforward design is one of its primary advantages, contributing to its widespread use in fluid handling and pneumatic systems. A standard quick connector typically consists of three core components: the body, an O-ring, and a collet. The O-ring and collet, located on either end of the fitting, are concealed within the connector’s body. To create a secure and reliable connection, tubing is inserted through the collet and O-ring before entering the fitting body. Together, these three elements form a tight, leak-proof seal that is critical for maintaining system integrity in both low-pressure and high-pressure applications.

When fluid or air pressure inside the tube increases, the collet is forced into a groove inside the fitting body. The resulting compression causes the collet’s tiny teeth to grip the tubing more tightly, making disconnection impossible unless the collet is released intentionally. The harder you pull on the tube, the tighter the collet holds. Meanwhile, the O-ring serves as the primary sealing element, preventing leaks by sealing the gap between the tubing and the body of the fitting. Proper insertion is key—if the tube is not fully inserted, leaks may occur, which is a common installation error in quick-connect systems.

Key Advantages of Quick Connect Fittings

- Tool-free installation: No need for wrenches or special tools, reducing downtime and maintenance costs.

- Consistent, reliable sealing: The O-ring and collet system ensures a secure, repeatable, leak-free connection every time.

- Versatile material options: Available in plastics (nylon, polypropylene, polycarbonate), brass, and stainless steel to suit different chemical compatibility and pressure needs.

Differences Between Male and Female Connectors

The primary distinction between male quick connect fittings and female quick connect fittings is the thread location. Female connectors have internal threads, while male connectors feature external threads. Selecting the correct gender is essential for compatibility with your system and for ensuring a secure, leak-free fit. Many quick disconnect couplings are designed in both male and female versions to accommodate a wide range of tubing, hose, or pipe configurations.

How Do Quick Connectors Prevent Leaks?

Proper installation is the key to leak prevention. The O-ring must be in good condition and the tubing fully inserted for the collet and O-ring to function as intended. For applications involving aggressive fluids or high pressures, choosing the correct material for both the O-ring (such as EPDM, Viton, or Buna-N) and the body (such as stainless steel or polypropylene) is critical. If you're experiencing leaks, review installation guidelines and consider whether your media or pressure exceeds the fitting's rated specifications.

Types of Quick Connectors: Finding the Right Fit for Your Application

Quick connectors are available in a wide variety of designs, materials, and connection mechanisms. The best quick connect coupling for your application will depend on your fluid or gas type, pressure requirements, space constraints, and the need for repeated connecting and disconnecting. Below are the most common types, each with unique features and use cases:

Push to Connect

Push-to-connect fittings—sometimes called push-in, push-fit, or instant fittings—allow tubing or hose to be connected simply by pushing it into the fitting body. The internal grip ring, typically made of stainless steel, bites into the tubing for a secure mechanical hold, while an integrated O-ring provides the fluid or air seal. To release, the collar or collet is pushed or pulled back, instantly disengaging the tubing. This design makes them extremely popular in pneumatic automation, water purification, beverage dispensing, and laboratory setups.

Unlike traditional compression fittings, push-to-connect fittings require no tools and are ideal for quick maintenance or system modifications, even in tight or concealed spaces. Common materials include acetal, polypropylene, and brass, offering chemical compatibility for water, air, and inert gases. These connectors are especially valued in applications where frequent reconfiguration is necessary, such as test benches, pilot plants, and modular industrial equipment.

Common Industries and Use Cases

- Water filtration and reverse osmosis systems

- Compressed air and pneumatic automation lines

- Beverage and foodservice equipment

- Modular laboratory and test setups

Are you looking for fast, tool-free plumbing connections? Explore our push-to-connect fitting options or contact us for application guidance.

Sleeve and Ball

This type of quick-release coupling uses a retractable outer sleeve (typically on the female side) and a spring-loaded ball latching mechanism. When the male and female halves are pressed together, the sleeve slides back, allowing the balls to seat in a groove on the male end, instantly locking the two halves together. To disconnect, simply pull back the sleeve, releasing the balls and separating the connection. This design offers secure, one-handed operation and is commonly used in hydraulic systems, pneumatic tools, and industrial fluid transfer lines.

Key Features

- Durable and robust brass or stainless-steel construction

- High cycle life for repeated connections and disconnections

- Often equipped with automatic shutoff valves to prevent spills or contamination

Not sure which sleeve and ball connector is right for your process? Ask our experts for help selecting the best quick disconnect for your line size and pressure rating.

Cam-Lock (Cam and Groove)

Cam-lock connectors—also known as cam and groove couplings—feature a simple yet effective locking system. The female half has folding cam arms that snap down onto a groove on the male adapter, creating a secure, threadless connection. No tools are required, making cam-locks ideal for transferring large volumes of liquids and dry materials quickly and safely. Typical applications include chemical processing, food and beverage transfer, fuel handling, and municipal water or wastewater systems.

Applications of Cam-Lock Fittings

- Tank truck and railcar unloading

- Fire hose and emergency water deployment

- Sewage and wastewater pumping

- Bulk chemical transfer

Luer Lock

Luer lock connectors are widely used in medical, laboratory, and research settings due to their precision and secure connection. The system consists of a tapered male and female fitting that either slides together (luer slip) or screws together (luer lock) for a reliable seal. The luer lock’s interlocking threads create a robust mechanical connection, minimizing the risk of accidental disconnection, leaks, or contamination. Typical materials include polypropylene, polycarbonate, nylon, and stainless steel to suit a variety of chemical and sterilization requirements.

These connectors are commonly found in hypodermic syringes, IV lines, catheters, feeding tubes, chromatography equipment, and ventilators. Their small size, secure fit, and compatibility with both liquids and gases make them indispensable in healthcare and scientific research. Luer fittings are also available in color-coded options for easy line identification and in both disposable and reusable designs.

When to Use Luer Lock Quick Connectors?

- For sterile, leak-proof medical line connections

- In laboratory equipment requiring precise, repeatable fluid transfer

- Where easy disassembly and reassembly are essential

Additional Types of Quick Connectors

In addition to the main categories above, there are several specialized quick connector types to consider for unique applications:

- Hydraulic quick couplers: Designed for high-pressure hydraulic fluid transfer in construction, agricultural, and industrial machinery. These are often equipped with dust caps and shutoff valves.

- Pneumatic quick disconnects: Used in compressed air systems for tools, automation equipment, and assembly lines. Available in various profiles (e.g., industrial, automotive, ARO, and Tru-Flate) for compatibility.

- High-purity quick connects: Utilized in pharmaceutical, semiconductor, and biotech processing where ultra-clean connections are required.

- Fuel line and chemical transfer couplers: Engineered with specific elastomers and metals for safe handling of aggressive chemicals, fuels, and solvents.

Benefits of Quick Connectors

Quick connectors provide numerous benefits that make them the preferred choice for modern fluid, gas, and vacuum systems. Here’s why they’re in such high demand:

- Wide range of configurations: Quick connectors are available in straight, elbow, tee, cross, and manifold versions, as well as different tube and thread sizes to match any system requirement.

- Time and labor savings: Fast, tool-free installation and removal drastically reduce assembly and maintenance time, boosting productivity and minimizing downtime.

- Leak prevention: Engineered O-rings and precision machined components provide reliable, long-term sealing performance—even under vibration and thermal cycling.

- Versatility: Suitable for water, air, hydraulic fluid, chemicals, and even vacuum lines in industries ranging from automotive and aerospace to food processing and life sciences.

- Enhanced safety: Features such as automatic shutoff valves, color coding, and positive locking mechanisms reduce risk of spills, cross-contamination, and accidental disconnection.

- Cost effectiveness: Lower labor costs, reduced need for specialized tools, and minimized fluid loss or contamination result in significant total cost of ownership savings.

Buyer’s Guide: What to Consider Before Purchasing Quick Connectors

- Media compatibility: Ensure your chosen material (plastic, brass, stainless steel) and O-ring (EPDM, Viton, Buna-N, FKM) are compatible with your fluid or gas.

- Pressure and temperature ratings: Verify that the connector meets or exceeds your system’s requirements for burst pressure and operating temperature.

- Connection type: Choose between push-to-connect, cam-lock, luer lock, or other styles depending on your application’s connection/disconnection frequency and required security.

- Size and flow rate: Select the correct tube or hose diameter and fitting size to avoid flow restrictions or excessive pressure drop.

- Regulatory and hygiene standards: For medical, food, or high-purity applications, verify compliance with relevant standards (FDA, NSF, USP Class VI, etc.).

Not sure how to match the right quick connector to your process? Contact our technical support team for personalized recommendations based on your exact application and performance requirements.

Choosing the Right Quick Connector Manufacturer

With so many options on the market, selecting the best quick connector supplier for your needs is essential for ensuring product quality, supply chain reliability, and technical support. Here’s how to make an informed decision when sourcing quick connectors:

- Evaluate manufacturer experience: Look for companies with a proven track record in your industry (e.g., medical, industrial, food processing) and with expertise in the specific connector types you require.

- Review material and quality certifications: Confirm that your supplier’s products meet relevant standards (ISO, FDA, RoHS, REACH) and offer full traceability for critical applications.

- Request technical support and customization: Leading manufacturers can assist with custom designs, material selection, and troubleshooting to optimize your system’s performance.

- Assess inventory and lead times: Reliable suppliers maintain sufficient stock and offer fast turnaround to avoid costly delays.

- Compare pricing and value-added services: Factor in engineering support, documentation, and after-sales service—not just unit price—when choosing a vendor.

To ensure a positive outcome when purchasing quick connectors from a manufacturer, compare at least 5 suppliers using our comprehensive quick connector directory. Each manufacturer profile highlights core capabilities, areas of experience, and provides direct contact forms for requesting information or quotes. Use our patented website previewer to quickly assess each company’s specialties, and submit our streamlined RFQ form to contact multiple suppliers with a single inquiry.

Would you like to compare top quick connector manufacturers for your project? Start your search here or speak with a sourcing specialist for tailored recommendations.

Frequently Asked Questions About Quick Connectors

What are the main applications of quick connectors?

Quick connectors are used in a wide range of applications, including fluid transfer in water and beverage systems, pneumatic automation, hydraulic machinery, medical devices, chemical processing, laboratory setups, HVAC systems, and more. Their versatility makes them a go-to solution wherever rapid, leak-free connections and disconnections are required.

How do I choose the right quick connector material?

The choice of material depends on your media (fluid or gas), required pressure and temperature ratings, and any regulatory or hygiene standards. For aggressive chemicals, stainless steel or specialized plastics may be necessary, while potable water lines often use food-grade polypropylene or acetal. Always consult with your supplier for compatibility data.

Are quick connectors reusable?

Most quick connectors are designed for multiple connect/disconnect cycles, though some (especially in medical or high-purity applications) may be intended for single use only. Always verify the manufacturer’s specifications regarding reusability and cleaning protocols.

What are the typical pressure and temperature ranges for quick connect fittings?

Pressure and temperature ratings vary by connector type and material. Pneumatic push-to-connect fittings often handle up to 250 psi and 175°F, while hydraulic couplings may exceed 5000 psi. Cam-locks and luer locks have their own specific ranges—always consult technical datasheets for exact performance limits.

Can I use quick connectors with aggressive chemicals or high-purity fluids?

Yes, but it’s critical to choose the correct material for both the body and O-ring. Look for connectors made from PTFE, FKM, FEP, or specialized alloys and confirm compatibility with your intended media. For high-purity applications, select connectors certified for low extractables and compliance with USP, FDA, or equivalent standards.

Ready to Source High-Quality Quick Connectors?

Whether you’re designing a new system or upgrading existing equipment, selecting the right quick connector can make a significant difference in performance, reliability, and maintenance costs. Quick connectors offer the speed, flexibility, and leak-free performance demanded by modern fluid and air handling systems. Use this guide to evaluate your needs, compare connector types, and choose a trusted supplier. Still have questions? Contact our team for expert support, or explore our directory of qualified quick connector manufacturers today.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services