Quick disconnect couplings are used in hydraulic systems for the transmission of pressurized hydraulic fluid, in pressure washers to connect spraying wands with water pressurizers and in many other different kinds of fluid transmission equipment. They are designed to make connections without allowing leakage or a loss in pressure. Read More…

Kent Rubber Supply has been a trusted supplier of industrial couplings and fittings since 1946. Offering all of the connections that you need for your industrial fitting, securement, accessories, and industrial coupling needs. Using our up-to-date assembly process, we can confidently supply all your coupling and fitting solutions.

At Ryan Herco Flow Solutions, we are dedicated to providing high-quality quick release couplings that keep our customers’ fluid handling systems operating with efficiency and reliability. Our quick release couplings are engineered to deliver secure, leak-free connections while allowing fast and easy disconnection, reducing downtime and simplifying maintenance across a wide range of applications.

At VACCO Industries, we take pride in being a trusted provider of precision-engineered solutions that serve demanding applications across aerospace, defense, and industrial markets. Our expertise extends to the design and manufacturing of quick disconnect couplings that are built to deliver reliable performance in critical environments.

At Dixon Valve and Coupling Company, we take pride in being a trusted leader in the design and manufacture of high-quality quick disconnect couplings that keep industries moving efficiently and safely. Our quick disconnects are engineered for reliability, allowing operators to easily connect and disconnect hoses, lines, and equipment without tools or leakage.

CEJN® manufactures several types of couplings, including quick connect couplings, hose couplings and hydraulic couplings that are applied in the areas of pneumatics, breathing air, hydraulics and other fluids. For over 40 years, we have been a mainstay for applications in pneumatics, water and chemicals.

Since 1969, Safeway, a division of The Specialty Mfg. Co. has been a manufacturer of quick action couplings, hydraulic couplings, and other quick couplings in a variety of materials and sizes, with numerous thread styles available. Our quick couplings are standard on skid-steer loaders, agricultural, construction, mining, rescue, mobile and off-shore equipment. All of our products are made 100%...

More Quick Disconnect Coupling Manufacturers

Comprehensive Guide to Quick Disconnect Couplings

Quick disconnect couplings, also known as quick disconnects or quick couplers, are essential components in fluid transfer systems across a wide range of industries. These versatile devices are used to rapidly connect and disconnect fluid lines with minimal effort, streamlining operations, improving safety, and ensuring reliable connections for the transport of various materials, including water, air, hydraulic fluid, fuel, and a wide range of chemicals.

If you’re searching for quick disconnect couplings for your application, understanding their types, benefits, features, and applications will help you make an informed decision. Whether you’re in the market for high-pressure hydraulic quick disconnects, pneumatic couplers, chemical-resistant fittings, or specialty connections for unique environments, this guide covers everything you need to know.

What Are Quick Disconnect Couplings?

Quick disconnect couplings are specialized mechanical fittings designed to be easily attached and detached from fluid or gas transfer lines. Their primary function is to enable rapid, tool-free connection and disconnection of hoses, pipes, or tubing, often with the use of just one hand. This makes them invaluable in applications where speed, efficiency, and safety are paramount.

How Do Quick Disconnects Work?

Quick disconnect couplings consist of two main parts: the male plug and the female coupling. To establish a secure connection, the male half is inserted into the female part, where internal mechanisms such as ball bearings, locking sleeves, or threaded collars engage to form a tight, leak-resistant seal. Disconnection is achieved by simply retracting or twisting the sleeve or collar, allowing for swift removal without the need for additional tools.

Key Benefits of Quick Disconnect Couplings

- Time Savings: The ease and speed with which quick disconnects can be connected and disconnected reduce downtime during equipment changeovers, maintenance, or repairs. This is especially important in fast-paced manufacturing and industrial environments.

- Leak Prevention: Many quick disconnect couplings are equipped with automatic shut-off valves that prevent fluid or gas leakage when the connection is broken. This feature protects valuable product, reduces waste, and enhances workplace safety.

- Safety: By minimizing the risk of spills and exposure to hazardous materials, quick couplers contribute to safer work environments for employees and protect the environment from accidental contamination.

- Versatility: Available in a wide range of sizes, materials, and pressure ratings, quick disconnects are suitable for everything from low-pressure air tools to high-pressure hydraulic systems and aggressive chemical processing.

- Tool-Free Operation: Designed for intuitive, one-handed operation, quick disconnects eliminate the need for wrenches or other tools, further streamlining workflow and reducing the risk of cross-threading or overtightening.

- Corrosion Resistance: Options in stainless steel, brass, aluminum, and engineered plastics ensure compatibility with corrosive substances and challenging environments.

Common Applications for Quick Disconnect Couplings

Quick disconnect couplings are used extensively in a broad range of industries and applications. Here are some of the most common uses:

- Agriculture: Used in irrigation systems, pesticide sprayers, and fluid transfer machinery for quick setup and breakdown.

- Automotive Manufacturing and Maintenance: Essential for fuel lines, brake systems, air conditioning recharge, pneumatic tools, and test equipment.

- Chemical Processing: Enables safe, spill-free transfer of aggressive chemicals, acids, and solvents with specialized materials and seals.

- Firefighting: Fast, reliable hose connections are crucial for emergency response and changing firefighting equipment on the fly.

- Food and Beverage Processing: Deployed in sanitary fluid transfer lines, where hygiene, speed, and easy cleaning are critical.

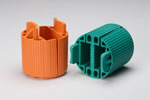

- Plastics Fabrication: Used in cooling circuits, pneumatic lines, and material transfer systems for injection molding and extrusion machines.

- Construction: Power pneumatic tools, hydraulic machinery, and water supply lines for dust suppression and concrete mixing.

- Laboratory and Medical: Facilitate quick changes and disconnections in analytical instruments, laboratory setups, and medical gas delivery systems.

- Marine and Aerospace: Provide secure, lightweight connections in fuel, hydraulic, and air systems where reliability and speed are vital.

Types of Quick Disconnect Couplings

When selecting a quick disconnect coupling, it’s important to match the connector type to your specific application requirements. Here are the most common designs:

- Push-to-Connect Couplings: These allow for immediate connection by simply pushing the two halves together, making them ideal for high-throughput assembly or maintenance operations.

- Threaded Quick Couplers: Featuring screw-tightened connections, these offer a higher degree of security and are often used in high-pressure hydraulic and pneumatic systems.

- Twist-Lock Couplings: Incorporate a simple twisting motion to secure the connection, providing convenience for applications that require frequent changes.

- Dry Break Couplings: Equipped with automatic shut-off valves on both halves, these prevent any fluid or gas losses during disconnection and are commonly used for hazardous chemicals, fuels, or sensitive fluids.

- Cam and Groove Couplings: Widely used for bulk fluid transfer in industrial, agricultural, and chemical applications. They provide a secure, leak-free connection with easy coupling and uncoupling.

- Bayonet Couplings: Utilize a push-and-twist action for quick, positive engagement, favored in medical, laboratory, and instrumentation uses.

- Non-Spill Couplings: Specifically engineered to prevent fluid drips or leaks, making them suitable for cleanroom or electronics manufacturing.

Choosing the Right Quick Disconnect Coupling: Key Decision Factors

With so many options available, selecting the ideal quick disconnect coupling for your needs involves careful consideration of several important factors:

- Fluid or Gas Type: What will be transferred? Ensure compatibility with water, air, hydraulic fluid, fuel, chemicals, or specialty media. Consult chemical compatibility charts for aggressive or hazardous substances.

- Pressure Rating: Match the coupling’s pressure capacity to your system’s maximum operating pressure. High-pressure hydraulic quick disconnects are designed for robust performance in demanding applications.

- Material Selection: Choose materials such as brass, aluminum, stainless steel, or plastic based on corrosion resistance, chemical compatibility, weight, and cost considerations.

- Temperature Range: Ensure the coupling can withstand your application’s minimum and maximum temperatures, especially in high-temperature or cryogenic environments.

- Connection Style: Decide between push-to-connect, threaded, cam and groove, or twist-lock based on your workflow and frequency of changeovers.

- Valve Type: Determine if you need automatic shut-off, dry break, or non-spill features to prevent leaks and protect operators.

- Size and Flow Requirements: Select the right diameter and flow capacity to optimize performance and minimize pressure drop.

- Industry Standards: Look for couplings that meet relevant certifications or standards, such as ISO, SAE, or FDA, especially for regulated industries like food, pharmaceutical, or aerospace.

- Cost and Availability: Balance performance and durability with your budget, and ensure replacement parts or additional units are readily accessible.

Looking for the best quick disconnect coupling for your system?

Ask yourself:

- What fluid, gas, or material am I transferring?

- Does my application require high pressure, high purity, or chemical resistance?

- Is ease of cleaning or sterilization important?

- Do I need a leak-proof, non-spill, or dry break coupling?

- Am I operating in a regulated environment with strict standards?

Materials & Construction: What’s Best for Your Application?

The choice of material for your quick disconnect coupling greatly impacts its longevity, performance, and compatibility. Here’s a detailed look at common options:

- Brass: Highly durable, corrosion-resistant, and suitable for water, air, and moderate chemicals. Widely used in industrial and automotive quick couplings.

- Stainless Steel: Offers superior resistance to corrosion, heat, and aggressive chemicals. Excellent for sanitary, food-grade, pharmaceutical, and marine environments.

- Aluminum: Lightweight and robust, often chosen for portable or weight-sensitive systems. Common in aerospace and mobile equipment applications.

- Plastic (Polypropylene, Acetal, Nylon): Corrosion-proof, lightweight, and cost-effective. Ideal for chemical processing, medical, and laboratory uses where metal may react with media.

- Specialty Alloys & Coatings: For extreme environments, specialized coatings or alloys (such as Hastelloy or PTFE lining) can provide added protection against corrosion or high temperatures.

Industry-Specific Use Cases and Best Practices

Each industry presents unique challenges and requirements for quick disconnects:

- Hydraulics: Heavy-duty hydraulic quick disconnects are engineered for high-pressure performance in construction, mining, and manufacturing machinery. Look for robust locking mechanisms and dust caps.

- Pneumatics: Pneumatic quick couplers are optimized for compressed air tools, automation lines, and robotics, featuring rapid connect/disconnect cycles and low pressure drops.

- Chemical Handling: Select couplings with specialized seals (Viton, EPDM, PTFE) and non-reactive materials to ensure safety and prevent leaks.

- Sanitary/Food & Beverage: Sanitary quick disconnects feature smooth, crevice-free designs to prevent bacterial growth and allow easy cleaning and sterilization.

- Medical/Laboratory: Leak-free, easy-to-clean connections are critical for sterile fluid transfer, medical gas delivery, and analytical instrumentation.

- Firefighting & Emergency Response: Durable, high-flow couplings enable rapid deployment and flexible hose management under pressure.

How do you maintain and inspect quick disconnect couplings?

Regular inspection and maintenance are vital to ensure the safe, leak-free operation of your quick disconnects. Follow these best practices:

- Inspect seals and O-rings for wear, cracks, or chemical degradation.

- Clean mating surfaces and locking mechanisms to prevent dirt buildup.

- Replace damaged or worn components promptly to avoid system failure.

- Lubricate moving parts as recommended by the manufacturer.

- Check for proper engagement and secure locking before pressurizing the system.

Frequently Asked Questions About Quick Disconnect Couplings

What is the difference between quick disconnect and standard couplings?

Quick disconnect couplings are specifically designed for rapid, tool-free connection and disconnection. Standard couplings, by contrast, typically require tools or multiple steps to assemble or remove, leading to greater downtime and potential for leaks if not handled properly.

Can quick disconnects handle high pressure and temperature?

Yes, many quick disconnect couplings are rated for high-pressure hydraulic or pneumatic applications and can withstand elevated temperatures. Always check manufacturer specifications for pressure and temperature ratings before installation.

Are there quick disconnects for aggressive chemicals?

Absolutely. Chemical-resistant quick disconnects are available in materials like stainless steel, polypropylene, and PTFE, often with specialty seals to ensure compatibility with acids, solvents, and other aggressive substances.

How do I prevent leaks when using quick disconnects?

Choose couplings with integrated shut-off valves or non-spill designs, ensure proper installation and regular maintenance, and select seals and materials compatible with your media.

How to Buy Quick Disconnect Couplings: A Step-by-Step Guide

- Define Your Application Requirements: List the fluids/gases, pressure, temperature, and size specifications for your system.

- Research Product Options: Compare different quick disconnect coupling types, materials, and brands suited to your needs.

- Request Technical Data Sheets: Obtain performance data, chemical compatibility, and pressure ratings to verify suitability.

- Order Samples: Test a small quantity in your actual environment to confirm fit, ease of use, and leak prevention.

- Consult Experts: Discuss your requirements with industry professionals or suppliers for tailored recommendations.

- Purchase and Install: Once satisfied, place your order and follow proper installation procedures to ensure reliable operation.

Ready to upgrade your fluid transfer system with reliable, high-quality quick disconnect couplings? Request a quote today or contact our technical team for personalized guidance.

Why Invest in Quality Quick Disconnect Couplings?

Investing in the right quick disconnect couplings delivers long-term benefits, including:

- Reduced maintenance costs due to fewer leaks and less wear

- Improved safety and compliance with industry regulations

- Faster changeovers and increased productivity

- Better protection of valuable equipment and product integrity

- Enhanced versatility for future system upgrades or expansions

Don’t compromise on system integrity or safety. Choose the right quick disconnects for your application—whether it’s for industrial, agricultural, chemical, food processing, or laboratory use—and experience the difference in performance, reliability, and peace of mind.

Still have questions?

For expert assistance, product selection advice, or custom solutions, contact our team today. Discover how the right quick disconnect coupling can transform your operation’s safety, efficiency, and bottom line.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services