Quick disconnect fittings are used for rapid and easy connection and separation of lines of fluid or air. Some manufacturers say these fittings are sometimes known as quick connections or rapid-release couplings. They are used to swap out fitting connections that need tools to put together and take apart. The two pieces of the fitting are automatically locked together when pressed together thanks to a spring-loaded ball latching mechanism built into them. Then, the sleeve is pulled back to disengage the connection, and the balls are unloaded. The benefit of a rapid disconnect is that one may complete the act quickly and manually. Read More…

Kent Rubber Supply has been a trusted supplier of industrial couplings and fittings since 1946. Offering all of the connections that you need for your industrial fitting, securement, accessories, and industrial coupling needs. Using our up-to-date assembly process, we can confidently supply all your coupling and fitting solutions.

At Ryan Herco Flow Solutions, we are dedicated to providing high-quality quick release couplings that keep our customers’ fluid handling systems operating with efficiency and reliability. Our quick release couplings are engineered to deliver secure, leak-free connections while allowing fast and easy disconnection, reducing downtime and simplifying maintenance across a wide range of applications.

At VACCO Industries, we take pride in being a trusted provider of precision-engineered solutions that serve demanding applications across aerospace, defense, and industrial markets. Our expertise extends to the design and manufacturing of quick disconnect couplings that are built to deliver reliable performance in critical environments.

At Dixon Valve and Coupling Company, we take pride in being a trusted leader in the design and manufacture of high-quality quick disconnect couplings that keep industries moving efficiently and safely. Our quick disconnects are engineered for reliability, allowing operators to easily connect and disconnect hoses, lines, and equipment without tools or leakage.

CEJN® manufactures several types of couplings, including quick connect couplings, hose couplings and hydraulic couplings that are applied in the areas of pneumatics, breathing air, hydraulics and other fluids. For over 40 years, we have been a mainstay for applications in pneumatics, water and chemicals.

Since 1969, Safeway, a division of The Specialty Mfg. Co. has been a manufacturer of quick action couplings, hydraulic couplings, and other quick couplings in a variety of materials and sizes, with numerous thread styles available. Our quick couplings are standard on skid-steer loaders, agricultural, construction, mining, rescue, mobile and off-shore equipment. All of our products are made 100%...

More Quick Disconnect Fitting Manufacturers

Comprehensive Guide to Quick Disconnect Fittings: Types, Applications, and Sourcing

Quick disconnect fittings, also known as quick release couplings or quick connect fittings, are essential components in fluid handling systems, pneumatic assemblies, hydraulic circuits, and industrial automation. With their ability to provide a fast, secure, and leak-proof connection between lines, quick disconnects have become indispensable in industries ranging from water treatment and food processing to chemical handling, automotive, and medical technology.

Are you searching for reliable quick disconnect couplings for your application? Or wondering how to select the best quick connect fittings for your needs? This guide covers everything you need to know about quick disconnect fittings, including their types, design considerations, installation methods, pressure and temperature limitations, typical use cases, and tips for choosing a reputable supplier.

Understanding the Mechanism: How Do Quick Disconnect Couplings Work?

When a coupling is clamp attached, it typically features a one-way sleeve designed for break-away disconnection using a tool. Two-way sleeves, on the other hand, enable easy, one-handed detachment—ideal for situations demanding rapid, tool-free connections and disconnects. By twisting and pulling the two ends of a two-way quick disconnect design, the connection is broken, allowing for efficient maintenance or replacement of system components.

The Design of a Quick-Disconnect Fitting

Quick-disconnect fittings—sometimes referred to as quick-release or quick-connect fittings—are engineered for convenient, repeated connections and disconnections without the need for specialized tools. Typically, a quick-connect fitting offers a semi-permanent seal to the tubing, making removal more challenging, while a quick-release fitting is intended for frequent disconnection. The core components include the coupling body and the insert: the insert snaps into the coupling body to form a secure, watertight (or airtight) seal. To release the fitting, simply press the latch and pull the assembly apart. This intuitive mechanism minimizes downtime and potential fluid loss.

In industries where uptime is critical, such as manufacturing, food and beverage, or laboratory filtration, the ability to quickly disconnect and reconnect lines is a major advantage. Whether handling water, hydraulic fluid, air, gas, or chemicals, the design of modern quick disconnect fittings ensures compatibility with a wide range of tubing and piping materials, including plastic, stainless steel, brass, and copper.

How Should a Quick-Disconnect Fitting Be Connected and Disconnected?

Proper installation and removal of quick-disconnect fittings is key to ensuring system integrity and safety. Depending on your water treatment, pneumatic, or hydraulic system configuration, manufacturers offer quick-release fittings tailored to different setups. For example, a copper tubing arrangement often requires a traditional compression fitting, while plastic tubing is best joined using a plastic compression nut and compatible quick connect coupling.

Always ensure there is ample space to complete the connection after fastening the components to the tubing, copper pipe, or manifold. If your quick-disconnect fitting includes an integrated valve, activate water or fluid flow by opening the valve after making the connection. With non-valve fittings, there is no need to operate a valve—the fluid will flow freely once the fitting is joined. To connect, insert the male fitting into the coupling body, then push until you hear an audible snap, indicating a secure seal. To disconnect, press the release clasp and pull the fittings apart.

Installation Best Practices for Quick Disconnect Fittings

- Verify compatibility between fitting material and the fluid being transported (e.g., water, oil, air, chemicals).

- Ensure tubing or piping is cut squarely and free of burrs to avoid leaks.

- Use manufacturer-recommended torque and assembly procedures, especially for high-pressure or safety-critical applications.

- Periodically inspect quick disconnect couplings for wear, corrosion, or seal degradation and replace as needed.

- Test newly installed fittings under pressure before full system operation.

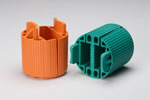

Types of Quick Disconnect Fittings: Explore Your Options

Quick disconnect fittings come in a variety of designs to accommodate diverse application requirements. Selecting the right type is crucial for safety, efficiency, and long-term reliability. Below are the most commonly used quick disconnect fitting types, each with unique features and benefits.

Snap-Type (Ball-Latching) Quick Disconnects

Snap-type quick connects, also called ball-latching couplers, are among the most popular options for fast, reliable connections in low- to medium-pressure systems. When two halves are pressed together, a spring-loaded ball mechanism locks them in place, ensuring a secure seal. To disconnect, simply pull back the release sleeve—both internal and external ends will instantly detach. This intuitive, one-handed operation is advantageous in applications where frequent connections and disconnects are required, such as pneumatic tools, laboratory equipment, and beverage dispensing. Snap-type quick disconnects typically handle pressures ranging from hundreds to thousands of pascals, depending on size and construction material.

Non-Latching Quick Disconnect Fittings

Non-latching quick disconnects are preferred in applications where frequent replacement or swapping of fluid lines is needed, such as laboratory testing, medical devices, or some pneumatic systems. These fittings often feature self-sealing valves that prevent leaks and fluid loss upon disconnection, maximizing safety and minimizing contamination risk. Variations include no-shutoff and single-shutoff designs, offering flexibility based on the specific application. Leading manufacturers produce a wide range of non-latching quick disconnect couplings for both single-use and reusable applications.

Single End Shutoff Quick Disconnects

Single end shutoff quick disconnects incorporate a valve in one half of the assembly (usually the internal half), which closes automatically to prevent fluid leakage. This design is ideal for filling chambers, releasing pressure from portable devices, or disconnecting supply lines without fluid loss. When employing single shutoff connectors, especially with hazardous or pressurized fluids, always use appropriate personal protective equipment (PPE) such as eye protection, as residual pressure may cause fluid ejection upon disconnection.

Double End Shutoff Quick Disconnect Fittings

Double end shutoff quick disconnects utilize valves on both the internal and external ends, ensuring fluid containment in both lines when the assembly is connected or disengaged. This design is especially valuable when handling expensive, hazardous, or sensitive fluids, as it minimizes leaks and exposure. While double shutoff couplings are highly effective, users should be aware that some fluid may still escape if lines are pressurized during disconnection, particularly from the shallow end. Common industries using double end shutoff quick disconnects include chemical processing, pharmaceuticals, food and beverage production, and hydraulic equipment.

Bayonet Quick Disconnect Couplings

Bayonet couplings provide a straightforward connection method for both pneumatic and high-pressure hydraulic systems. The user pushes the two ends together, then twists them a quarter turn to lock the male end into the female socket. For disconnection, a simple quarter turn in the opposite direction releases the coupling. This robust mechanism is favored in pneumatic circuits, gas lines, and certain hydraulic applications where vibration resistance and quick serviceability are required.

Flat Face Quick Connect Couplings

Flat face quick disconnects are designed to eliminate trapped pressure and prevent fluid or air leakage. By removing the cavity where fluid or air can accumulate, these couplings reduce the risk of contamination and provide a cleaner, safer operation. Flat face designs are available in both threaded screw-in and push-to-connect formats, offering high flow rates and minimal pressure drop. Additionally, their sleeve-locking feature reduces the risk of accidental disconnection—making them ideal for hydraulic systems in construction, agricultural machinery, and heavy equipment.

Common Applications and Use Cases for Quick Disconnect Fittings

Quick disconnect fittings support a wide variety of industries and processes. Here are some of the most common and high-value applications:

- Water Treatment Systems: For rapid maintenance, filter changes, and system upgrades with minimal downtime and risk of leaks.

- Hydraulic Equipment: Including heavy machinery, construction vehicles, and agricultural implements requiring robust, high-pressure connections.

- Pneumatic Tools and Automation: Fast, tool-free changes of air hoses and actuators in manufacturing, automotive repair, and robotics.

- Medical Devices: Safe, sterile connections for IV lines, dialysis, and diagnostic equipment.

- Food and Beverage Processing: Sanitary quick disconnects for beverage dispensing, dairy lines, and brewery equipment.

- Chemical Handling: Leak-proof, corrosion-resistant couplings for transporting acids, solvents, and hazardous fluids.

- Laboratory and Analytical Equipment: Modular connections for gas, liquid, and vacuum lines.

- Automotive and Aerospace: Fast service and testing connections for fuel, oil, and coolant lines.

Quick-Disconnect Fittings Have a Pressure and Temperature Limit: What to Consider

Quick-disconnect fittings are rated for operation at specific pressure and temperature ranges. The maximum allowable pressure depends on the fitting design, material, and connection method (e.g., barbed, compression, or threaded). High temperatures can reduce the pressure capacity of both the fitting and the tubing, so always consult the manufacturer's specifications before selecting a product for demanding environments.

For example, barbed connections are generally less pressure-resistant than threaded or compression types. Plastic quick disconnects may be suitable for water and low-pressure air, while brass and stainless steel quick disconnects are preferred for high-pressure hydraulic or chemical service. It's essential to match the fitting's pressure and temperature ratings to your application's requirements to maintain system safety and efficiency.

- Ask: What pressure and temperature ratings do I need for my quick disconnect coupling?

- Consider: Is my fluid corrosive or hazardous? Choose chemical-resistant materials like stainless steel, brass, or specialized polymers.

- Evaluate: Will my application involve frequent connections and disconnections, or will the line remain static for long periods?

Material Choices for Quick Disconnect Fittings: Which is Right for You?

Quick disconnect fittings are available in a variety of materials, each suited to specific environments and fluid types:

- Plastic (Polypropylene, Nylon, Acetal): Lightweight, cost-effective, and corrosion-resistant. Ideal for potable water, food processing, and some chemicals.

- Brass: Durable, corrosion-resistant, and suitable for air, water, and non-aggressive fluids. Used extensively in plumbing and industrial applications.

- Stainless Steel: Superior chemical resistance and high-pressure capability. Preferred in pharmaceutical, chemical, and hydraulic systems.

- Aluminum: Lightweight and strong, but less corrosion-resistant. Used in some pneumatic and air tool applications.

Wondering which material is best for your quick disconnect fitting application? Consult with your manufacturer or supplier to ensure compatibility with your process fluids and operating environment.

Key Benefits of Using Quick Disconnect Fittings

- Reduced Downtime: Rapid, tool-free connections and disconnections speed up maintenance and system changes.

- Leak-Free Operation: Precision-engineered seals and valves minimize fluid loss and contamination.

- Enhanced Safety: Self-sealing designs prevent accidental spills and exposure to hazardous substances.

- Versatility: Suitable for water, air, hydraulic fluid, fuel, chemicals, and more.

- Improved Productivity: Modular connections facilitate system upgrades and repairs without disrupting the entire process.

- Custom Configurations: Available in various sizes, materials, and shutoff options to meet specific requirements.

Decision Factors: How to Select the Right Quick Disconnect Fitting

Choosing the optimal quick disconnect fitting depends on several critical factors. Ask yourself the following questions to narrow your options:

- What type of fluid (water, oil, air, chemicals) will the fitting handle?

- What are the system’s maximum pressure and temperature requirements?

- Will the connection be subject to frequent coupling and uncoupling?

- Is resistance to corrosion, abrasion, or aggressive chemicals necessary?

- What is the required flow rate, and will the fitting introduce unacceptable pressure drop?

- Is the application sanitary or does it require special certifications (e.g., NSF, FDA, ISO)?

- What is the tubing or piping size, and is compatibility with existing system components required?

For detailed technical advice or custom solutions, contact a knowledgeable quick disconnect fitting supplier with your specifications.

Choosing the Proper Quick Disconnect Fitting Supplier

To ensure you achieve the best results when purchasing quick disconnect fittings, it’s important to evaluate multiple quick disconnect fitting suppliers. Use our comprehensive quick disconnect fitting supplier directory to compare at least five companies. Each supplier profile highlights their core expertise, product range, manufacturing capabilities, and available certifications.

- Use our contact form to request technical data, pricing, or a custom quote from any supplier.

- Review each business website using our patented website previewer to assess their specialization, product inventory, and service reputation.

- Utilize our RFQ (Request for Quote) form to send a single inquiry to multiple quick disconnect fitting businesses, streamlining your sourcing process.

- Look for suppliers with a proven track record in your industry, strong technical support, and flexible delivery options.

Still have questions about sourcing or specifying quick disconnect fittings? Contact our industry experts for personalized assistance, application engineering, and product recommendations.

Frequently Asked Questions About Quick Disconnect Fittings

- What are the benefits of using quick disconnect fittings over traditional threaded couplings?

Quick disconnects provide faster installation, reduced risk of leaks, less wear on system components, and easier maintenance. - Can quick disconnect fittings be used for both liquids and gases?

Yes, they are available for a wide range of fluids, including water, oil, compressed air, steam, fuel, and chemicals. Always choose a fitting with appropriate seals and materials. - How can I ensure compatibility with my existing system?

Check the fitting’s size, thread type, pressure and temperature rating, and material compatibility. Consult with your supplier if unsure. - What is the difference between single shutoff and double shutoff quick disconnects?

Single shutoff has a valve on one side, while double shutoff has valves on both sides, offering greater leak prevention during disconnection. - Do quick disconnect fittings require maintenance?

Periodic inspection for wear, corrosion, and seal integrity is recommended. Replace worn or damaged fittings promptly.

Explore More Resources

- Browse our directory of leading quick disconnect fitting manufacturers and suppliers

- Read our technical guide to quick disconnect coupling selection

- See all frequently asked questions about quick release and quick connect fittings

- Contact our technical team for application support and custom solutions

Conclusion: Unlock Efficiency and Safety with the Right Quick Disconnect Solution

Quick disconnect fittings have revolutionized fluid transfer, pneumatic control, and hydraulic systems across countless industries. By offering rapid, secure, and leak-free connections, they dramatically reduce downtime, enhance operator safety, and increase system flexibility. Understanding the types of quick disconnect couplings available, their benefits, and the key factors that affect selection will enable you to make informed decisions for your next project or equipment upgrade.

Ready to source high-quality quick disconnect fittings? Compare suppliers, download technical datasheets, and request product samples today to ensure the highest performance and reliability in your application.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services