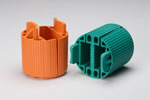

The use of quick disconnect can hasten the installation of hydraulic and pneumatic lines. The male and female halves (nipple and coupler) of a quick disconnect combine to produce a complete coupling. Usually made of metal, coupling halves consist of a body, a latching mechanism, an end connection, and a valving mechanism. Read More…

Kent Rubber Supply has been a trusted supplier of industrial couplings and fittings since 1946. Offering all of the connections that you need for your industrial fitting, securement, accessories, and industrial coupling needs. Using our up-to-date assembly process, we can confidently supply all your coupling and fitting solutions.

At Ryan Herco Flow Solutions, we are dedicated to providing high-quality quick release couplings that keep our customers’ fluid handling systems operating with efficiency and reliability. Our quick release couplings are engineered to deliver secure, leak-free connections while allowing fast and easy disconnection, reducing downtime and simplifying maintenance across a wide range of applications.

At VACCO Industries, we take pride in being a trusted provider of precision-engineered solutions that serve demanding applications across aerospace, defense, and industrial markets. Our expertise extends to the design and manufacturing of quick disconnect couplings that are built to deliver reliable performance in critical environments.

At Dixon Valve and Coupling Company, we take pride in being a trusted leader in the design and manufacture of high-quality quick disconnect couplings that keep industries moving efficiently and safely. Our quick disconnects are engineered for reliability, allowing operators to easily connect and disconnect hoses, lines, and equipment without tools or leakage.

CEJN® manufactures several types of couplings, including quick connect couplings, hose couplings and hydraulic couplings that are applied in the areas of pneumatics, breathing air, hydraulics and other fluids. For over 40 years, we have been a mainstay for applications in pneumatics, water and chemicals.

Since 1969, Safeway, a division of The Specialty Mfg. Co. has been a manufacturer of quick action couplings, hydraulic couplings, and other quick couplings in a variety of materials and sizes, with numerous thread styles available. Our quick couplings are standard on skid-steer loaders, agricultural, construction, mining, rescue, mobile and off-shore equipment. All of our products are made 100%...

More Quick Disconnect Manufacturers

Quick Disconnects: Complete Guide to Types, Applications, and Benefits

Quick disconnects, also known as quick couplers or quick disconnect fittings, are essential components used across a wide range of industries to enable fast, secure, and leak-free connections between fluid, gas, or pneumatic lines. These versatile fittings are designed for efficiency, safety, and reliability in connecting and disconnecting hoses, tubing, and piping systems without the use of tools. Whether used for hydraulic equipment, pneumatic tools, medical devices, or industrial processes, selecting the right quick disconnect coupling is crucial for system performance and longevity.

The most widely used material for quick disconnects is carbon steel, valued for its strength and durability in demanding industrial environments. However, due to their superior corrosion resistance, brass and stainless steel quick disconnects are also frequently utilized, especially in applications exposed to harsh chemicals or moisture. Understanding the distinction between the male and female halves of rapid disconnects is vital to ensure compatibility and performance. In fluid handling and hydraulic systems, the male quick disconnect typically features external threads, while the female quick disconnect has internal threads—though this can vary depending on the connection standard and industry.

What Are Quick Disconnects Used For?

Quick disconnects are widely implemented in systems where the following goals and operational efficiencies are desired:

- Fast, tool-free connection and disconnection of fluid or gas lines

- Minimizing downtime and maximizing productivity during equipment changeovers

- Preventing leaks and spills for enhanced workplace safety and environmental compliance

- Reducing maintenance time and costs by enabling easy access to system components

- Improving process reliability and repeatability in sensitive or mission-critical applications

Easiest Way to Connect and Disconnect Lines

Quick couplers offer a practical and secure alternative to reinstalling hose-end connectors, especially in systems that require frequent joining or removal of lines. This is particularly advantageous for field equipment and portable machinery, where access to tools may be limited. Some thread types, such as NPT (National Pipe Thread), are intended for single-use and can experience thread wear or deformation with repeated assembly. Using quick disconnects designed for repeatable coupling and uncoupling helps prevent leaks, reduces wear on system components, and accelerates installation and maintenance.

Prevention of Spills and Leak Control

Spilled hydraulic oil, transmission fluid, chemicals, or other process media not only poses safety hazards but also results in costly material loss and potential environmental fines. Quick disconnects with integrated shut-off valves or dry break features are engineered to minimize fluid loss during disconnection, reducing the risk of equipment downtime, contamination, and costly cleanups. Choosing the right quick disconnect coupler can help reduce leakage during line changes, improve equipment uptime, and ensure regulatory compliance in sensitive environments.

Key Applications of Quick Disconnects

Because of their adaptability and robust engineering, quick disconnects are suitable for almost any application involving hydraulic or pneumatic lines, fluids, or gases. Industries relying on quick disconnect fittings include automotive, agriculture, manufacturing, medical, food and beverage, chemical processing, and more. Below are some of the most common—and critical—use cases for quick disconnect couplings:

- Truck and trailer air brake systems

- Pressure washing equipment

- Hydraulic tools and attachments

- Agricultural machinery and irrigation systems

- Industrial process equipment

- Medical and laboratory devices

- Semiconductor manufacturing lines

- Gas detection and analytical instrumentation

Semiconductor Manufacturing Equipment

The semiconductor manufacturing process involves the controlled handling of chemicals, de-ionized water, gases, and heat transfer fluids—all under strict temperature and pressure requirements. Quick disconnects used in this industry must deliver high purity, corrosion resistance, and leak-free operation to prevent contamination and ensure process reliability. Semiconductor equipment manufacturers often specify high-performance stainless steel quick disconnects with advanced sealing technologies for critical fluid management applications.

Hydraulic and Pneumatic Tools and Compressors

Quick disconnects are perhaps most commonly associated with pneumatic and hydraulically powered tools and equipment. If you’ve visited an auto repair shop or seen a snow plow in action, you’ll likely notice a quick release coupling at the end of the fluid lines. These fittings make it simple to switch between different tools or attachments, improving workflow efficiency and minimizing equipment downtime. Many hydraulic quick disconnects incorporate safety lock features and pressure-rated seals to handle high-pressure environments reliably.

Food and Beverage Packaging Machinery

In the food packaging industry, maximizing machine uptime is critical to profitability. Packaging equipment is often designed for continuous operation, and any unplanned downtime for repairs or changeovers can result in substantial lost revenue. Sanitary quick disconnects designed for food and beverage applications allow operators to quickly swap out components, clean, or sterilize lines without sacrificing productivity. Features such as clean-in-place (CIP) compatibility and FDA-approved materials are often required in these environments to ensure safety and compliance.

Industrial Gas Detectors and Analytical Equipment

For worker safety, it’s essential to sample ambient air before entering confined spaces such as manholes, mines, or chemical storage areas. Gas detection equipment often employs long probe lines connected via quick disconnects, enabling users to easily switch probes and sample lines for the detection of hazardous gases like carbon monoxide, hydrogen sulfide, methane, and oxygen. These fittings are also widely used in aerospace, semiconductor, chemical processing, pharmaceutical, and medical sectors for gas sampling and analysis. Selecting the right gas quick disconnects is vital for ensuring reliable, contamination-free measurements.

Medical and Laboratory Blood Analysis Systems

Modern medical diagnostics rely on automated blood analyzers and fluid transfer systems that require frequent connection and disconnection of tubing. Quick disconnects provide secure, sterile, and reliable connections to prevent cross-contamination and minimize downtime during maintenance or troubleshooting. Medical-grade quick disconnects are manufactured from biocompatible materials such as polypropylene or polycarbonate, and are available with non-spill valves to maintain system integrity.

Chemical and Analytical Testing Methods

Equipment used for purity testing, water and air analysis, or chemical composition assays often incorporates quick disconnects to streamline the switching of sample lines and reagents. These systems demand leak-proof performance and chemical compatibility, often requiring the use of PTFE, stainless steel, or high-purity polymers. Quick disconnects in analytical labs help ensure accurate, repeatable results and simplify equipment servicing.

Dental Equipment and Procedures

Dental chairs, ultrasonic descalers, anesthesia machines, and drills all use quick disconnect tubing to transport water, compressed air, and anesthetic gases. When equipment needs cleaning, sterilization, or maintenance, quick disconnects enable rapid removal and reconnection of critical system components. This speeds up turnaround time and increases productivity for dental professionals, while also supporting stringent hygiene requirements.

How to Select the Right Quick Disconnect Fitting

Choosing the appropriate quick disconnect fitting for your application requires careful consideration of several factors. Here are key decision points to help guide your selection process:

- Material Compatibility: Will your application expose the fitting to aggressive chemicals, high pressures, or temperature extremes? Select from stainless steel, brass, plastic, or specialty alloys based on required corrosion resistance and mechanical properties.

- Seal Type: Does your process demand O-ring seals, flat-face seals, or dry break technology to minimize fluid loss and contamination?

- Connection Style: Consider whether you need push-to-connect, threaded, cam-lock, or bayonet-style quick disconnects for optimal ease of use and reliability.

- Pressure and Temperature Ratings: Ensure the quick disconnect fitting is rated for the maximum system pressure and operating temperature in your application.

- Flow Requirements: Match the internal diameter and flow rate capacity of the quick disconnect to your system demands to avoid restrictions.

- Regulatory and Safety Standards: For food, medical, or hazardous applications, verify that the quick disconnect complies with relevant standards such as FDA, NSF, or ISO.

Need help choosing the right quick disconnect? Contact our technical team for personalized assistance or request a sample to evaluate product performance in your unique application.

Frequently Asked Questions about Quick Disconnects

Looking for quick answers about quick disconnect couplings? Explore these common search-driven questions:

- What is the difference between a quick disconnect and a quick connect fitting? In most contexts, these terms are used interchangeably. Both refer to fittings enabling fast, tool-free attachment and removal of hoses or tubing.

- How do I identify the right size quick disconnect for my system? Measure the outside diameter of your hose or tubing and match it to the fitting’s nominal size. Always confirm compatibility with both ends of your system.

- Are there quick disconnects for high-pressure hydraulic applications? Yes, specialized hydraulic quick disconnects are designed to handle pressures exceeding 5,000 psi, often with locking mechanisms and pressure-release features for safety.

- Can I use quick disconnects with aggressive chemicals or corrosive fluids? Choose materials such as stainless steel, PTFE, or other chemically resistant polymers for compatibility with harsh substances.

- What are dry break quick disconnects? Dry break couplings incorporate valves that close automatically upon disconnection, preventing fluid loss and minimizing spills—ideal for hazardous or expensive fluids.

- Where can I buy quality quick disconnect fittings online? Visit our supplier directory to compare leading quick disconnect fitting manufacturers and request quotes for your project.

Benefits of Using Quick Disconnects

Implementing quick disconnects in your fluid, gas, or pneumatic systems delivers measurable advantages for maintenance, operations, and safety:

- Reduced Downtime: Faster changeovers and servicing minimize production delays and increase equipment availability.

- Improved Safety: Leak-free connections and easy shut-off features limit operator exposure to hazardous fluids and reduce environmental risks.

- Lower Maintenance Costs: Quick disconnects reduce thread wear on system connections and simplify troubleshooting, repairs, and part replacement.

- Enhanced Versatility: Compatible with a wide range of tubing and hose materials, quick disconnects support modular system designs and frequent reconfiguration.

- Process Efficiency: High-flow designs and minimal pressure drop help maintain optimal system performance in critical applications.

Comparing Quick Disconnect Types: Which Is Best for Your System?

There are several types of quick disconnect couplings, each suited to specific use cases and fluid handling requirements. Common categories include:

- Single Shut-Off: Incorporates a valve on one side to stop flow when disconnected. Ideal for pneumatic tools and general industrial use.

- Double Shut-Off: Valves on both halves prevent fluid loss from either side, commonly used in hydraulic lines and sensitive fluid transfer systems.

- Dry Break: Advanced couplings designed to virtually eliminate drips or spills during connection and disconnection—critical for hazardous materials and cleanroom environments.

- Non-Valved: Basic design without internal shut-off, offering the highest flow rates for low-risk applications.

Not sure which quick disconnect type is right for you? Explore our in-depth comparison guide or ask our experts for tailored recommendations based on your project.

Industry-Specific Quick Disconnect Applications

Automotive and Transportation

Quick disconnects are essential in automotive assembly lines, truck air brake systems, and fuel transfer lines. Their ability to facilitate rapid maintenance and minimize downtime makes them invaluable for fleet operators and maintenance teams.

Agriculture and Irrigation

Agricultural machinery, irrigation systems, and fertilizer distribution equipment rely on quick disconnects for fast equipment changeovers and field repairs. Corrosion-resistant fittings, such as brass and stainless steel, are preferred for outdoor and chemical exposure environments.

Manufacturing and Industrial Automation

In automated manufacturing environments, quick disconnects support modular assembly, tool changes, and quick reconfiguration of robotic lines. Their reliability and efficiency are crucial for maintaining high production throughput.

Laboratory and Research

Lab setups often require frequent changes of tubing and apparatus. Quick disconnects with chemical-resistant seals and precise flow control ensure reproducible results and safe sample handling.

Conclusion

Quick disconnects are invaluable for increasing productivity, safety, and operational efficiency across a wide range of industries and fluid handling systems. By minimizing connection time, reducing leaks, and supporting easy equipment maintenance, these couplings deliver substantial value for manufacturers, operators, and service professionals alike. Material selection, seal compatibility, and application requirements should all be carefully considered when specifying quick disconnect fittings for your project.

How to Choose a Reliable Quick Disconnect Fitting Supplier

Choosing the right supplier is crucial for ensuring product quality, technical support, and timely delivery. Follow these steps to make an informed purchasing decision:

- Compare at least five reputable quick disconnect fitting suppliers using our curated supplier list.

- Review each supplier’s business profile to assess experience, manufacturing capabilities, and industry certifications.

- Use our website previewer to quickly evaluate the supplier’s product range, technical resources, and support services.

- Submit our simple RFQ (Request For Quote) form to contact multiple suppliers and compare pricing, lead times, and customization options.

- Request product samples or technical datasheets to verify performance in your specific application.

Ready to source quick disconnects? Start your supplier comparison or contact us for personalized recommendations tailored to your industry and application.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services